It also aids in sealing. The purpose of the design is to overcome the possibility of ring sticking the configuration allowing the side clearance to alter as the ring moves in the groove preventing carbon build up.

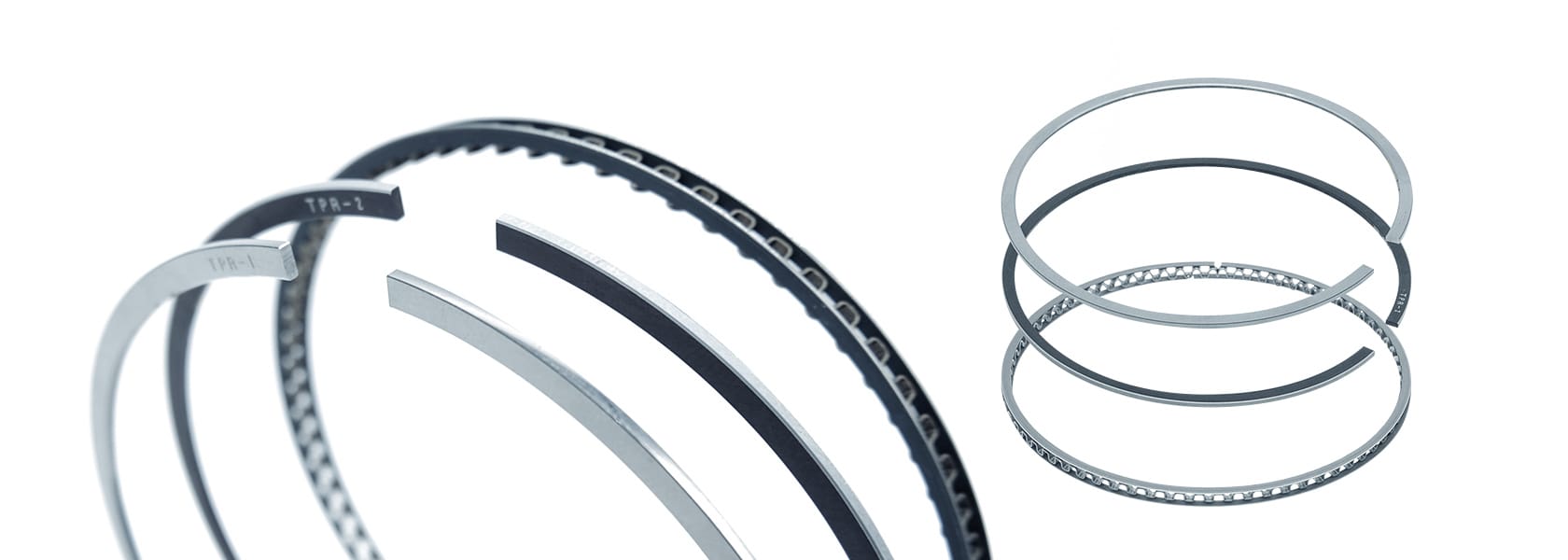

Piston Ring Types Compression Ring

Another study evaluated ring breakage in a diesel engine 10.

. It aids in oil control. The up and down motion of the piston keeps the keystone ring loaded in the ring groove of the piston and as a byproduct also keeps the ring groove clean from the soot of the diesel fuel. The effects on oil consumption of keystone piston rings dimensioned for OD contact with the piston groove have been compared to the effects of keystone rings dimensioned for ID contact with the groove in a statistically designed experiment utilizing a diesel engine at two different power output levels.

The design of keystone rings and grooves as shown in SAE Standard J929 are compared with some modified de-signs for diesel and heavy duty engines. The rings usually have butt joints but in some heavy-duty engines the joint may be angled lapped or of the sealed type. A ring-dynamics and gas-flow model has been developed to study ringgroove contact blowby and the influence of ring static twist keystone ringgroove configurations and other piston and ring parameters.

Barrel Face has a curved face OD of a ring that makes contact with the cylinder wall. Idealo ist Deutschlands größter Preisvergleich - die Nr. It is also known to taper an entire outer peripheral.

In order to minimize groove wear the grooves may be anodized or a nickel-based alloy ring groove insert may be cast into the aluminum piston. Folge Deiner Leidenschaft bei eBay. It is known to design a piston ring having a cross section in the shape of a keystone ie.

The dynamics of the top two rings and the gas pressures in the regions above the oil control ring. However keystone rings of necessity experience more vertical motion in the ring groove and may result in significant groove wear. Friction is still and issue but because the width of the.

The design of keystone rings and grooves as shown in SAE Standard J929 are compared with some modified designs for diesel and heavy duty engines. Ad Unsere günstigsten Preise für Piston pistons rings und ähnliches vergleichen. The piston rings are split so that they can be expanded and slipped over the piston head and into the recessed grooves cut in the piston.

Several studies analyzed the behavior and lubricating oil consumption of keystone rings in diesel engines 5-9. The groove finish and angle ranging between 12. Early steam engines used a hemp packing to seal the combustion chamber which caused high frictional resistance and did not provide a very effective seal.

Torsionalthis compression ring has an ID bevel causes twisting action and aids in sealing. The keystone shape allows the expanding gases to more easily force the piston ring radially outwardly. Piston Ring Sets 472016.

The dimensioning of keystone piston rings and grooves is discussed. The first use of a piston ring in the cylinders of a steam engine appears in 1825 by Neil Snodgrass a Glasgow engineer and mill-owner for use in his own machinesThis used springs to keep the seal steam-tight. A proposed standard is offered to eliminate problems encountered due to the vari- ations in current designs.

The insert may be used for the top ring alone or for both compression rings. Keystone piston rings are being used extensively in heavy duty diesel engines to avoid ring sticking. SB014 Keystone Rings and Piston Grooves Many diesel engines use a piston that has one or more taper-sided compression ring grooves.

B Flush or line-to line contact where. Napier has a hook-shaped design on the lower face of second compression rings. Learn more about the piston rings we manufacture below.

A proposed standard is offered to eliminate problems encountered due to the variations in current designs. Engines and air compressors pistons. However we found no report examining ring breakage.

The dimensioning of keystone piston rings and grooves is discussed. If youre questioning the set you need our engineers can recommend the right one out of the thousands we offer. Keystone rings are classified into three types of ring to groove side contact depending on how the keystone angle tolerance is determined.

Therefore engine and piston ring designers should design the keystone ring taking into account not only wear resistance but also breakage resistance. The purpose of the design is to overcome the possibility of ring sticking the configuration allowing the side clearance to alter as the ring moves in the groove preventing carbon build up. A compression ring with a wedge cross section.

The model is developed for a ring pack with three rings. Our rings function in sets usuallya top compression ring second groove compression or oil scraper ring and oil control ringand range from 1125 to 8875 bores. SB014 Keystone Rings and Piston Grooves Many diesel engines use a piston that has one or more taper-sided compression ring grooves.

1 für den besten Preis. Piston Cylinder Keystone ring h 3 a 6 15 β a 1 SC 2 H l Piston Cylinder Keystone ring a 7 a Piston vertical axis is coincident with cylinder axis b Piston land contacts with cylinder wall. The Keystone system was initially conceived as a gravity wall system that could be constructed to heights of up to 65 feet 2 m.

The original Keystone Standard unit was 2 feet 600 mm from face to tail providing weight and stability to resist the applied earth pressures. The piston ring is one or more seals that circle the piston head to create a seal. Ad Schau Dir Angebote von Piston Ring auf eBay an.

A Outer seal or front-edge bearing contact where the ring angle is greater than the groove angle. The design of keystone rings and grooves as shown in SAE Standard J929 are compared with some modified de- signs for diesel and heavy duty engines. Home Pistons 2017 Technical Manual Piston rings.

Piston Rings Piston Rings Komarov S R O

High Quality 98mm Std Piston Rings For Perkins A4 236 Buy Std Piston Ring Piston Rings For Perkins A4 236 34 12 745760m91 739858 Bepco 745760m91 41158041 41158029 86775 92463 R34760k Ae 800016211000 Ks 043 26 N0 04375n0 87 315000 4 Product On

What Happens If The Piston Rings Have Been Put Upside Down In A Car Engine Quora

Experimental Piston Rings Download Table

0 comments

Post a Comment